Manceps for Manufacturing

Skyrocket Throughput,

Optimize Supply Chain,

Accelerate Research and Development

Since the rise of the internet, the world’s top-producing factories have prioritized digital transformation. Now, terabytes of data flow from almost every tool on the factory floor, giving organizations more information than they know what to do with.

Unfortunately, many companies lack the resources to translate this torrent information into actionable insights that reduce costs and increase efficiency. For that, companies need Artificial Intelligence. Manceps bridges the knowledge gap, making it easy for manufacturers to put their data to work.

WHAT'S DRIVING THE URGENCY TO ADOPT AI?

High revenue volatility • Need to continuously find cost savings • Short production times • Increased regulation and inspections • Learning and adaptability on the factory floor • Manufacturing capacity and supply chain demands • Increased need for small-batch and/or customized goods.

THE FACTORIES OF THE FUTURE CAN:

Detect defects throughout the production process.

Deploy predictive maintenance

to reduce down-time.

Respond to real-time changes in demand across the supply-chain.

Validate whether

intricate goods like microchips have been perfectly produced.

Reduce costs of

small-batch or single-run goods, enabling greater customization.

Improve employee satisfaction by shifting mundane tasks to machines.

APPLICATIONS

Defect Detection

Today, many assembly lines have no systems or technologies in place to identify defects across the production line. Even those which may be in place are very basic, requiring skilled engineers to build and hard-code algorithms to differentiate between functional and defective components. The majority of these systems cannot learn or integrate new information, resulting in countless false-positives, which then have to be manually checked by an on-site employee.

By imbuing this clunky system with artificial intelligence and self-learning capabilities, manufacturers can make huge leaps in quality control efficiency.

Quality Assurance

Manufacturing requires acute attention to detail, a necessity that’s only exacerbated in the electronics space. Historically speaking, quality assurance has been a manual job, requiring a highly skilled engineer to ensure that electronics and microprocessors were being manufactured correctly and that all of its circuits were properly configured.

Today, image processing algorithms can automatically validate whether an item has been perfectly produced. By installing cameras at key points along the factory floor, this sorting can happen automatically and in real-time.

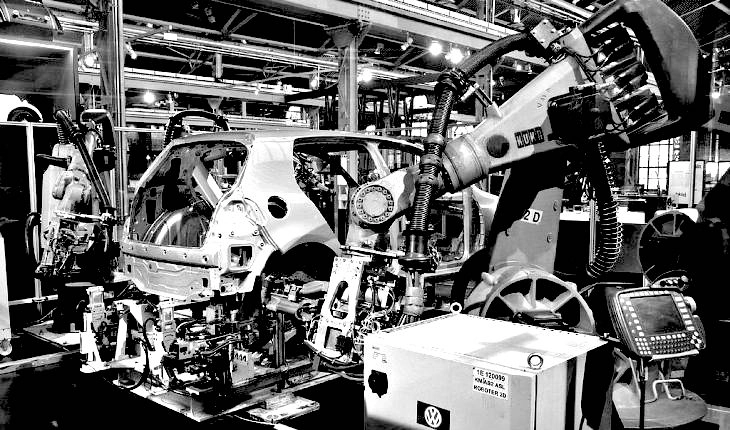

Assembly Line Integration

Today, much of the equipment that manufacturers use sends a vast amount of data to the cloud. Unfortunately, this information tends to be siloed and doesn’t play nicely together.

Getting a holistic picture of your operation requires several different dashboards and a subject matter expert to make sense of it all.

By creating an integrated app that pulls data from the breadth of the IoT-connected equipment you use, you can ensure that you’re getting a God-like view of the operation.

Assembly Line Optimization

Furthermore, by layering in Artificial Intelligence into your IoT ecosystem, this wealth of data, you can create a variety of automations. For example, when equipment operators are showing signs of fatigue, supervisors get notifications. When a piece of equipment breaks down, the system can automatically trigger contingency plans or other reorganization activities.

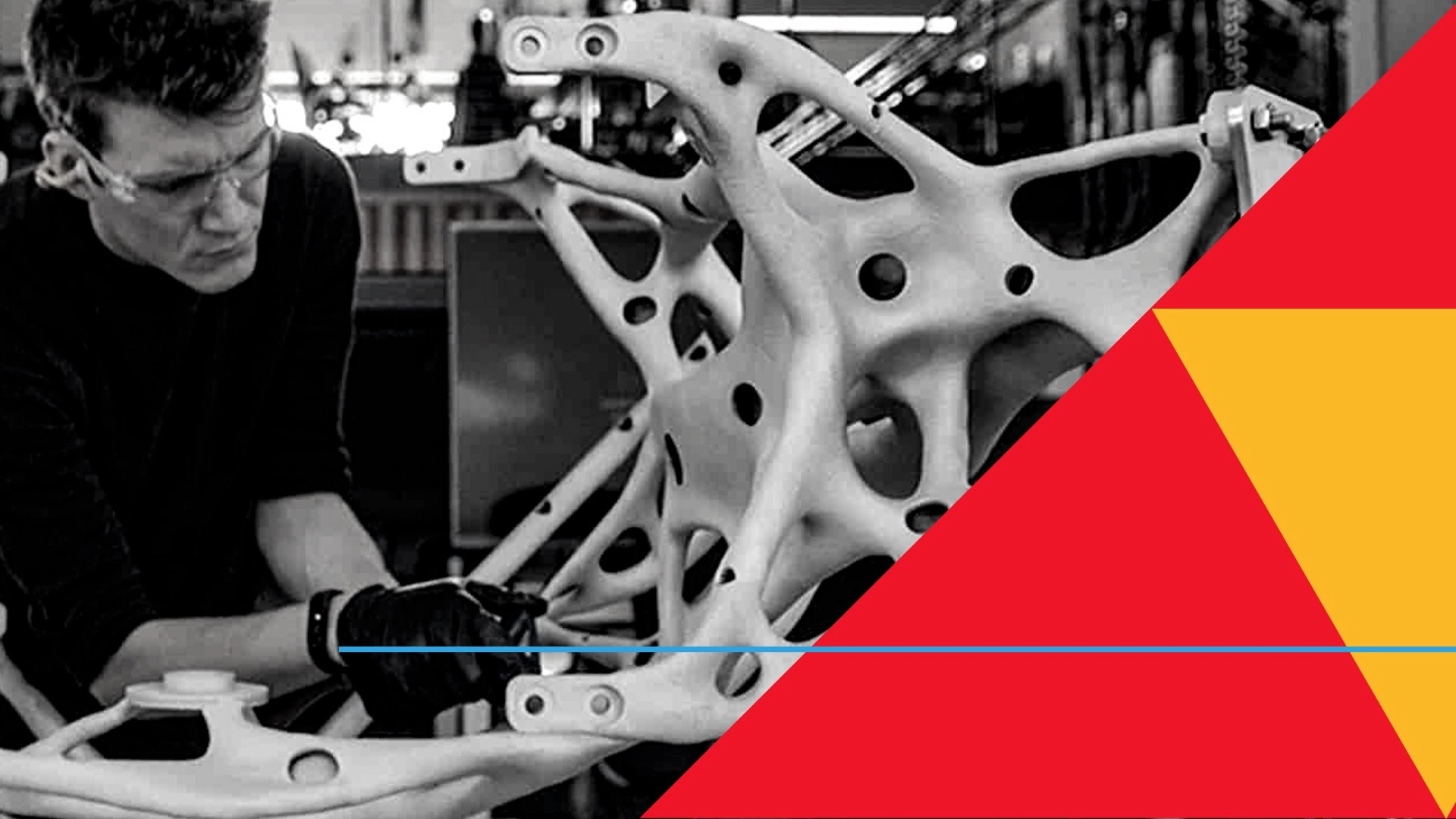

Generative Design